Heat Recovery Steam Generators

Compact Size, Low Weight, Fast Startup, Easily Cleaned & Low Maintenance.

Engine Exhaust Gas Boiler

Featured Item

Waste Heat Recovery Steam Generators

Built from the coil sections of Clayton’s fired steam generators, these units are used for higher exhaust gas inlet temperatures up to 3,000°F, and are capable of handling exhaust gas flows in the general range of 1,000 to 30,000 lbs./hr. They can be supplied with refractory-lined ducting and various configurations of inlet/outlet arrangements. Additional economizer sections can be added to enhance performance to best suit the application.

Call today to learn more about Clayton Waste Heat Boilers and industrial boilers heat recovery steam generators.

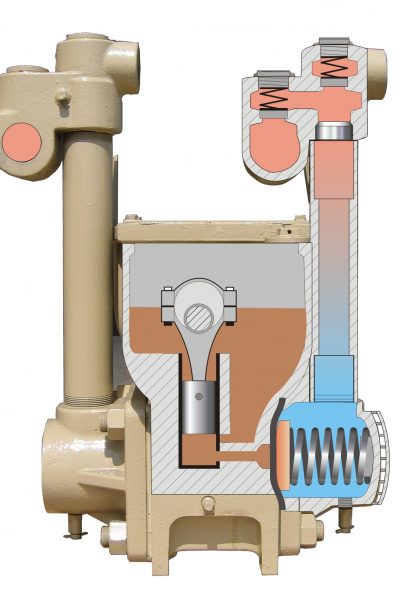

Pumps / Steam Separator / Acccumulator / Drum Equipment

Ancillary System Equipment

Both types of Waste Heat/Exhaust Heat Recovery Steam Generators are normally provided with skid-mounted feedwater pumps and steam separator/accumulator or Steam Drum components. Additionally, complete feedwater treatment systems are provided to assure proper treatment and handling of system flow.

All Clayton Steam Generators and Exhaust Gas Boiler Products under 10 MW in capacity and 10 MPa in design pressure are classified under the AS2953 Boiler – Safety management and supervision systems standard as under the Unattended Operation Category.

For quotations, contact your local Clayton representative.

World Class

Service, Support and Parts’

The sun never sets on Clayton’s and our local Representative’s Service and Support Teams worldwide. Replacement parts, planned or emergency services, Annual Inspections and more are available and comply to Australian Standards to keep your Clayton Steam Generator or Exhaust Gas / Waste Heat Boiler operating to its peak efficiency.